A proper nozzle height is imperative to maintaining the sheet’s health and longevity. Make sure to properly level your nozzle to the bed such that it doesn't dig in and damage the surface (It's durable but not invincible). If you are printing with the Bambulab X1C, currently the Pro Plate is designed to use the "Smooth PEI / High-Temp Plate” profile on the Bambulab slicer and shouldn’t give you any issues.

BuildTak

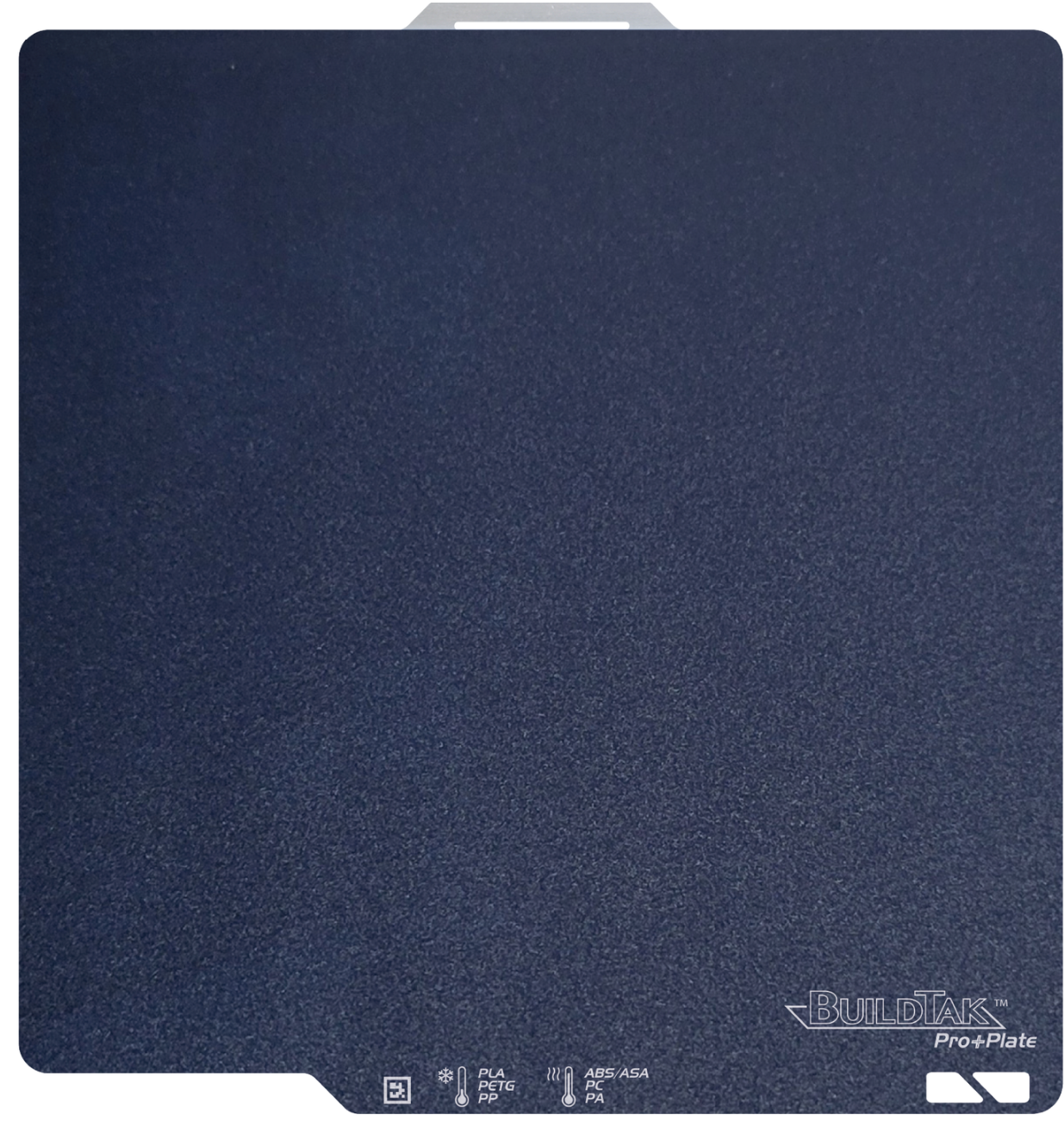

BuildTak ProPlate

BuildTak ProPlate

Couldn't load pickup availability

BuildTak Pro Plate – Ultimate 3D Print Surface

The BuildTak ProPlate features a metal FlexPlate base, a permanent adhesive layer, and an enhanced BuildTak Plus+ PA/PC sheet with a permanent top coating for unmatched multi-material compatibility. Enjoy flawless adhesion with ABS, PLA, PETG, ABS, PA-CF, PC, and more – all with easy removal and no harsh cleaning required.

Best Practices

Check your nozzle height

Assisted Removal

If you need to use a removal tool we recommend something like our BuildTak Spatula or equivalent rounded-metal spatula. Note the surface is durable to withstand general usage, but excessive force and digging into the surface can damage the surface after prolonged use. In order to maintain the life of your sheet, we recommend flexing to expose an edge or corner of the print and gently pushing with the spatula.

NO SOLVENTS/CLEANERS

When cleaning surfaces we recommend against using any solvents like Acetone or Windex as they can both damage it. With this surface in particular, we recommend cleaning with just a microfiber cloth to remove dust particles. 70% alcohol will make the surface tacky and can cause visual marring. It can help with adhesion with some materials that might give you issue but we don’t recommend cleaning with it.

Settings

| Material | Bed Temp |

|

ABS/ASA |

80-100°C |

|

PC |

80-100°C |

|

PETG |

Cold-100°C |

|

PLA |

Cold-60°C |

|

PA/PA-CF |

50°C |

|

PP |

100°C then Cold |

Please note these are just recommendations and a place to start. Experimentation might still be required to get the ideal result.

Included

BuildTak Plus+ PA/PC sheet adhered to metal FlexPlate base. Magnetic base not included.